Hedhvick Hirav

Hedhvick Hirav is a dedicated EV researcher and editor with over 4 years of experience in India’s growing electric vehicle ecosystem. Their contributions have been recognized in leading sustainability publications and automotive journals.

Summarize & analyze this article with

Choose an AI assistant and open this article directly:

Tip: if the AI doesn’t fetch the page automatically, paste the article URL manually.

BLDC Motor in Electric Vehicles: The Complete 2025 Guide

Introduction: Beat of the Indian electric vehicular movement

India is quickly transitioning to sustainable mobility anxiety to fast-track the green revolution and the leading it is the electric vehicle (EV). Whether it is a lightweight two-wheeler zipping through the streets of its city or an electric car that a family can take on a vacation, the BLDC motor is at the heart of almost all modern EVs. This technology, also referred to as Brushless DC Motor is the technology that is gradually propelling the road towards clean and efficient transportation.

Then why are the electric vehicles in India built on the basis of BLDC motors? How are they superior to conventional motors and what do they have to do with your daily driving? This article demystifies secrets of the BLDC motor in EVs, explains the benefits, and shortcomings, and gives practical information capable of being referred to by manufacturers, purchasers, or the interested individuals.

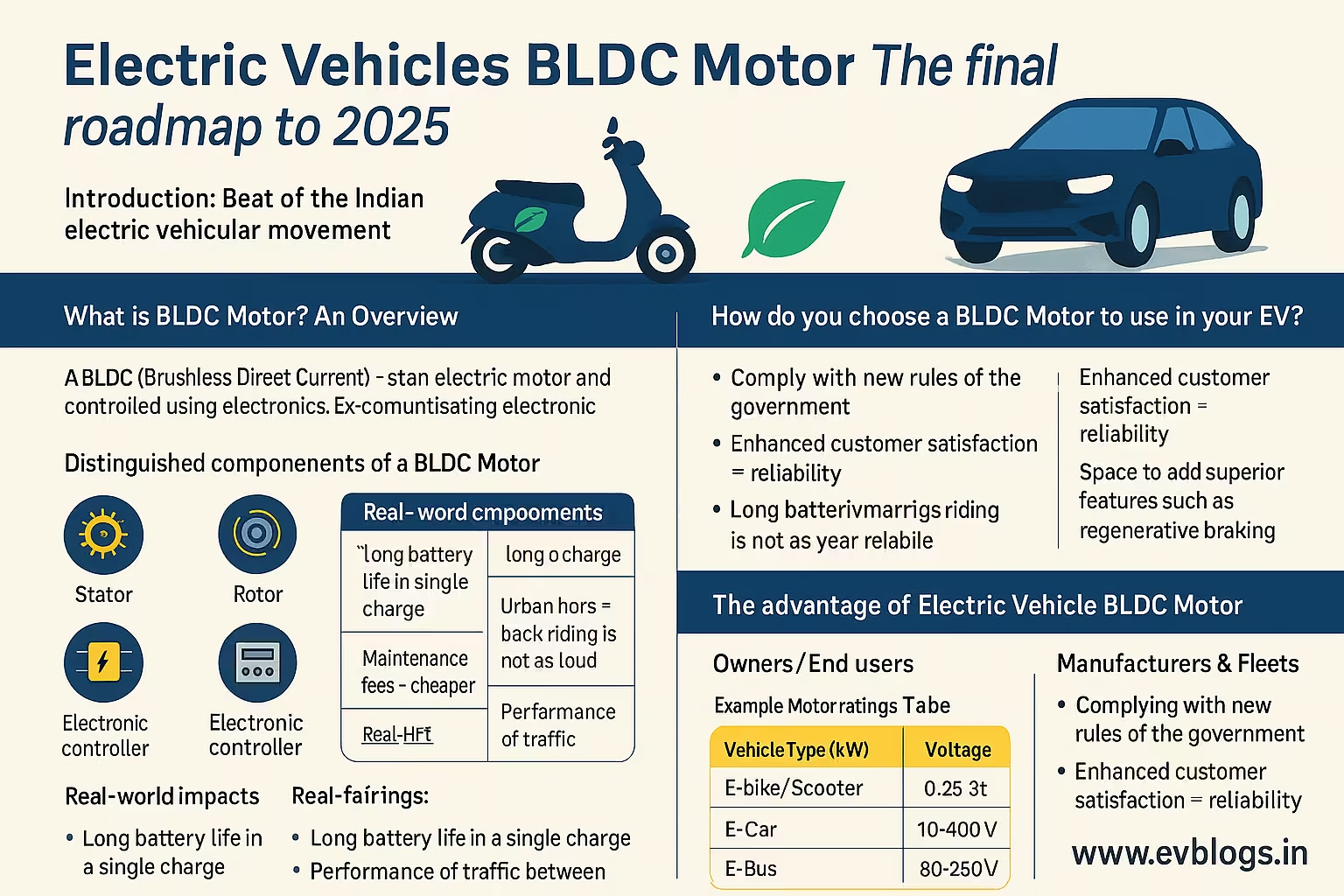

What is BLDC Motor? An Overview

A BLDC (Brushless Direct Current) motor is the electric motor which is powered using direct current (electricity), and controlled using electronics as compared to mechanical brushes. The BLDC motor is contrasted with the conventional brushed DC motors, wherein the brushes do not physically switch current to the rotating component (rotor) of the motor but instead the commutation is electronic.

Distinguished components of a BLDC Motor

- Stator: Stationary component that has coil.

- Rotor: permanent magnet rotating part.

- Electronic Controller: eliminates brushes and permits control of the current either in sensors or sensorless algorithms.

What is BLDC Motor?

- The stator windings allow current to pass through them on the controller.

- This in its turn generates a magnetic field.

- The rotor (permanent magnets) follows this moving field arousing motion as a result.

- It is more efficient and has less maintenance as the design eliminates friction generating components (like brushes).

What is so cool about BLDC Motors in Electric Vehicles?

Advantages DC Motors Brushed Compared to

| What is common | Brushed DC Motor | BLDC Motor |

|---|---|---|

| maintenance | high (brushes) | low (no brushes) |

| Life span | Short | Long |

| Noise | Loud | Silent |

| Power Density | Less | More |

Long battery life in a single charge

Real-World Impact

These would be the advantages to the Indian purchasers and fleet operations of EVs:

- Maintenance fees - cheaper

- The urban horseback riding is not as loud.

- The performance of traffic between stop and start position is more reliable

BLDC Motors are used in Electric Vehicles

- In India, the BLDC motors find use in more than 90 percent of electric two-wheelers in the year 2024.

- Most of the big Indian EV companies use high efficiency BLDC drives, including Ola Electric, Ather Energy, and Tata Motors.

- The greater range and reliability is facilitated by the central government policies which include FAME II incentive with high-efficiency motors.

- Advances such as sensorless control are reducing the price of BLDC motors to mass-market.

Outer Rotor/Inner Rotor designs

Inrunner and Outrunner applications

- Inner Rotor: center rotating core of non-rotating windings; used in e-cars also, which need greater torque.

- Outer rotor: Magnets rotate and are encased in fixed windings; (used in e-bikes/scooters because of the size).

An Example of Motor Ratings Table:

- Inrunner: faster, less torque- better where cars and buses use.

- Out runner: Higher low speed torque- found in scooters and e-rickshaws.

| Vehicle Type | Vehicle Power (kW) | Voltage |

|---|---|---|

| E-bike/Scooter | 0.25 3 | 24-72 V |

| E-Car | 10-50 | 72-400 V |

| E-Bus | 80 - 250 | 400-600 V |

How do You Choose a BLDC Motor to Use in Your EV?

The following ones should be taken into consideration:

- Power Rating (kW): This is just synonymous to the weight of the vehicle and the acceleration required.

- Voltage: High voltage can be termed more power, however, it requires proper batteries.

- Torque Requirements: Urban commuter, and mountainous roads are not equal.

- Cooling: The heavy vehicles may need the finest cooling facilities.

- Smart Compatibility: Be Smart enough to become compatible with the electronics of your car.

Eligibility/ Standards: Are All EVs powered by BLDC Motors?

Most of the modern Indian EVs have BLDC motors due to their efficiency; however, it is not a legal requirement but is highly encouraged by the indoctrination of the industry generally and government incentives.

The advantage of Electric Vehicle BLDC Motor

- AIS 138: Sets out traction motors performance and safety requirements of EVs being sold in India.

- FAME II Incentives: Subsidies that are extra on vehicles that have high efficiency motors like BLDC.

By whom they are to be used?

- The FAME subsidies or exports require these standards by manufacturers.

- The change of fleets with BLDC powered fleet is the most advantageous to the fleet operators whose target at low total cost of ownership.

Owners/ End Users

- Long Range: As much as 15-20 percent more efficient than brushed equals fewer charging.

- Less Maintenance: with no brushes, it will have fewer wears and tears; it will need servicing only once a year.

- Long Life: Is constructed to go over 10 years without much trouble.

- Smooth Drive: One can overtake or go up a hill very easily, the swift response in torque allows you to do so.

- Less Noisy Operation: Appropriate where there are heavily populated places or where there is no noise.

Manufacturers & Fleets

- Enhanced customer satisfaction reliability

- The space to add the superior features such as regenerative braking

- Better average warranty claims as there are less break downs

How a BLDC Motor can be mounted in Electric Vehicle?

Ms Priya Dey - EV Manufacturing Specialist:

Requirement Analysis

Specify the definition of torque speed, voltage requirements (by type and application of vehicle).

Motor Selection

Choose inner/outer rotor type; choose power rating that is appropriate to battery pack.

Controller Integration

Electric controller of the program to keep the precise speed/torque; add safety equipment like thermal cut offs.

System Testing

Tough bench-testing and on road testing in real life conditions.

Certification & Compliance

Fast prototypes to AIS certification; make FAME qualified, in case of incentives wanted.

Production Rollout

Start the large scale production when everything is finally proved to be proper; quality must be well taken care of.

2025 Trends

- Change to sensorless control algorithms, to conserve more money

- And more power density by developing ultra-lightweight magnet materials

- Better utilization beyond the two wheelers to buses and commercial fleets

- Be observant to full recycling materials due to new sustainability demands

Hints and Suggestion To Buyers And Owners

To The Potential Buyers:

- No EV purchase should be made without asking what kind of motor the device utilizes ask to inspect certified high-efficiency motors.

- Compare ratings on efficiencies (seek more than 85 percent).

- Enquire about warranty that covers traction motor and controller unit in particular.

To Present Proprietors:

- Take time to put in place regular checks even during those times when maintenance is hardly necessary- especially check cooling systems before summer.

- Visit authorized service centers which know the specific controller software / hardware combination of your car.

- Make sure that you are aware of any firmware updates released by the manufacturer which could be an update to make the vehicle more driveable or could be a firmware that unlocks new features via over-the-air update.

To Fleet Managers:

- Track overall cost over time per km-a quality BLDC system will tend to save on operation cost up to 30 percent within five years compared to legacy systems.

- Consider the brands having remote diagnostics or telematics and the fundamental motor guarantee.

Comparison: contrasting between other popular types of motors to that of BLDC motors in EVs

| Parameter | Brushed DC | Induction Ac | Permanent Magnet Synchronous (PMSM) | Brushless dc (BLDC) |

|---|---|---|---|---|

| Price | Cheap | Middle | Expensive | Middle |

| Efficiency | Low | Medium | High | High |

| Maintenance | High | Medium | Low | Very low |

| Usage | Practically never in this and era | Buses/High Power | Exotic Cars | Most Indian EVs |

Note: PMSM motors are very much like BLDC, only the rotor is built differently and control is more involved; however, the two are both highly efficient and PMSM can be slightly more efficient at extreme powers (luxury cars).

Indian Success stories and Uses

- Ather Energy scooters have proprietary developed outer rotor BLDC motors which enable the scooters to accelerate quickly and the weight remains low, and this is one of the factors that makes the scooters popular to the young urban riders.

- Tata Nexon EV has powerful inner rotor types and advanced controllers, which have made it able to perform on a highway equipped with assistance that does not reduce the driving range in the city, therefore its superiority in the family e-car sales ranks under Rs 20 lakh.

- The locally produced sensorless BLDC drives used in Delhi NCR Smart e-rickshaws have since the transition to the FAME II policy also reduced downtime by 50 percent over the earlier induction-motor variant.

Frequently Asked Questions (FAQ)

Q1: Is a BLDC motor fitted on every electric car?

Not every EV has a BLDC motor, but most new two-wheelers and many passenger cars do with the benefit of efficiency (as compared to older technologies like brushed DC or induction motors).

Q2: How long do a typical automotive grade BLDC motor last?

This type of motors can be easily designed to last over ten years or over one lakh kilometers in routine conditions of usage with proper care taken.

Q3: Will a Himalayanbike/scooter be able to retrofit to a BLDC motor kit?

In fact, a couple of vendors offer retrofit kits that have certification to use small, outer rotor form-factor BLDC motors that will fit popular scooters/bikes–but again, check with local RTO first before making the conversion.

Q4: What are the disadvantages of BLDC motor?

Purchase price can be a little high when compared to certain other alternatives; however, sophisticated electronic controllers require professional servicing in case of failures; however, this is offset by the economies in fuel consumption and maintenance charges over a period.

Q5: Will any charging stations communicate with a vehicle which has a BLDC motor?

Well–you see, it is all a matter of charging standard–that is, the battery system in your car–not the traction motor employed.

Action-oriented Conclusion & Conclusion

The electric mobility revolution sweeping across India however would not be possible without such innovations as the brushless DC (BLDC) motor, a technology that holds the potential to be the most efficient, the most durable, the most silent, and most importantly, to the health and productivity of our cities moving forward.

Whether it is your initial e-scooter or an entire fleet replacement, understanding how and why BLDC drives work puts you a step ahead as an informed consumer or practitioner in this ever-evolving marketplace of 2025.

Do not compromise on certified manufacturers who have invested their money in the designs of more advanced motor technologies as per the government specifications- not only will you have a better range in your start up today, but you will also help to make India a smarter and greener nation in the future.

Sources

- Ministry of Heavy Industries – FAME India Scheme Guidelines

https://heavyindustries.gov.in/user_index.aspx?id=11&lid=41&lang=1 - Automotive Research Association of India – AIS Standards

https://www.araiindia.com/standards.php - Society of Manufacturers of Electric Vehicles – Technical Resources

https://www.smev.in/ - Ather Energy Technical Blog

https://blog.atherenergy.com/ - Tata Motors Electric Mobility Portal

https://ev.tatamotors.com/ - IEEE Spectrum – “How Brushless DC Motors Work”

https://spectrum.ieee.org/how-brushless-dc-motors-work