Hedhvick Hirav

Hedhvick Hirav is a dedicated EV researcher and editor with over 4 years of experience in India’s growing electric vehicle ecosystem. Their contributions have been recognized in leading sustainability publications and automotive journals.

Summarize & analyze this article with

Choose an AI assistant and open this article directly:

Tip: if the AI doesn’t fetch the page automatically, paste the article URL manually.

NEW DELHI, Dec 15 — As the world pivots towards greener technologies, electric vehicle (EV) battery recycling has emerged as a cornerstone of China’s sustainable development agenda. With India closely watching its neighbour’s progress, the Chinese model offers important lessons on how recycling can drive economic and environmental gains. Here are the key ways in which EV battery recycling is powering China’s sustainable future.

1. Strengthening Resource Security and Reducing Import Dependence

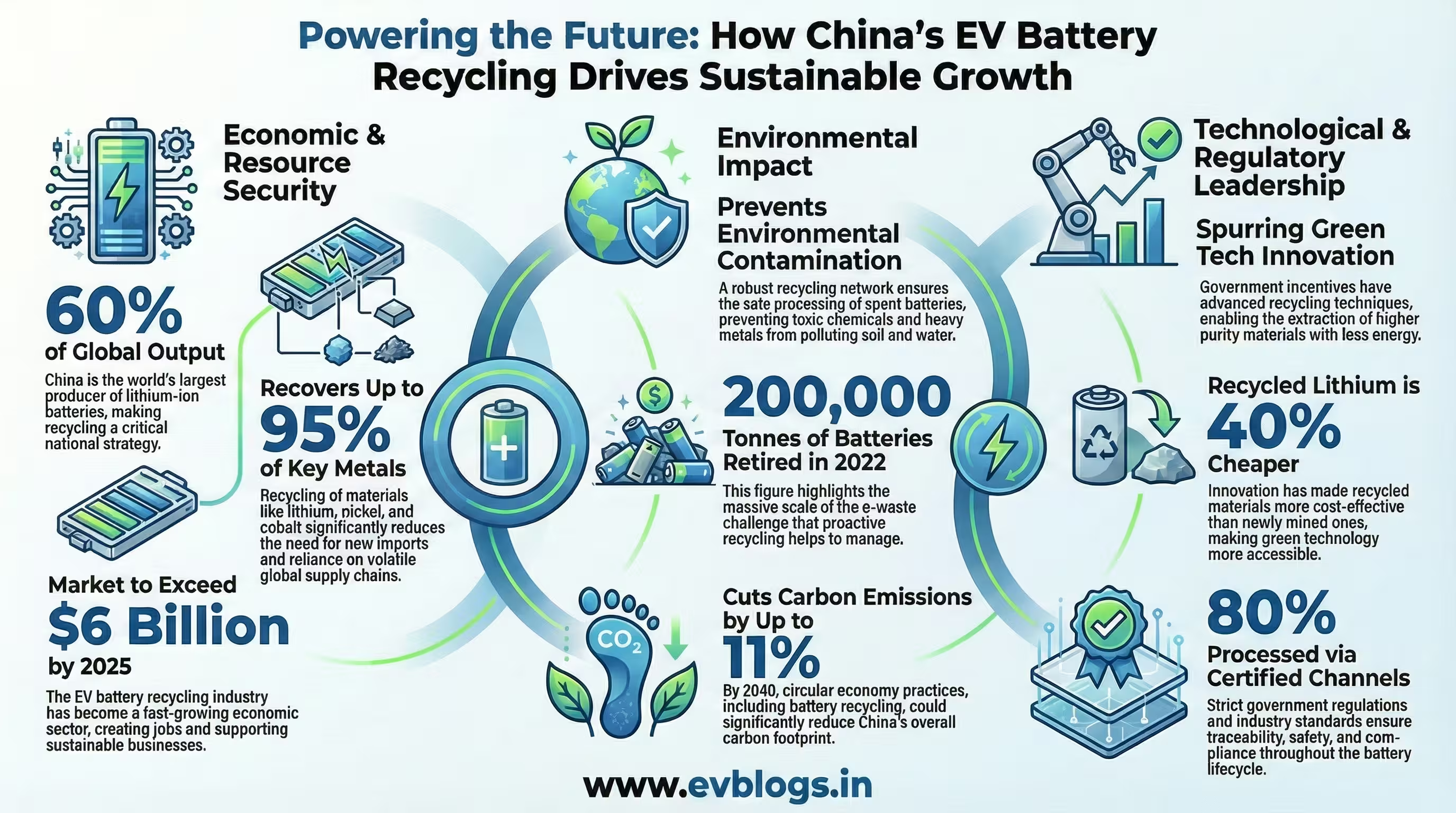

China is the world’s largest consumer and producer of lithium-ion batteries, accounting for over 60% of global output. By investing in EV battery recycling, the country is able to recover valuable materials such as lithium, nickel, and cobalt, which are critical for manufacturing new batteries.

“Recycling can recover up to 95% of key battery metals, significantly reducing the need for fresh imports,” according to industry estimates.

This approach helps China minimise reliance on volatile global supply chains, a lesson highly relevant for India, which currently imports most of its battery components.

2. Mitigating Environmental Impact and Reducing Waste

China faces mounting challenges from electronic waste, with EV batteries posing a unique hazard due to toxic chemicals and heavy metals. By establishing a robust recycling network, China is able to safely process spent batteries and prevent environmental contamination.

Over 200,000 tonnes of EV batteries reached end-of-life in China in 2022, highlighting the scale of the recycling challenge.

This proactive approach not only protects soil and water but also aligns with India’s growing focus on environmental stewardship as the nation aspires to meet its own net-zero ambitions.

3. Spurring Innovation in Green Technologies

The Chinese government has incentivised investment in advanced recycling techniques such as hydrometallurgy and direct regeneration. These innovations make it possible to extract higher purity materials and reduce energy consumption during battery production.

The cost of recycled lithium is now up to 40% lower than newly mined lithium, making green technologies more accessible.

Indian technology startups and manufacturers can learn from China’s investment in R&D, fostering local innovation in battery management and recycling.

4. Creating New Economic Opportunities and Jobs

EV battery recycling has become a fast-growing industry in China, generating employment and supporting the growth of sustainable businesses. Leading Chinese firms like CATL and GEM Co. have rapidly expanded their recycling operations, servicing both domestic and international markets.

The EV battery recycling market in China is projected to exceed $6 billion by 2025.

India, with its large workforce and entrepreneurial ecosystem, can tap into similar opportunities by developing local recycling hubs and skill development programmes.

5. Enhancing Circular Economy and Sustainable Manufacturing

China’s push for battery recycling is part of a broader shift towards a circular economy. By reusing and repurposing materials from spent batteries, the country is closing the resource loop and promoting sustainable manufacturing.

Circular economy practices could reduce China’s carbon emissions by up to 11% by 2040, as per recent studies.

India’s policy makers are increasingly recognising the need for circularity, particularly as the country’s EV market is set to grow at a CAGR of over 40% in the coming years.

6. Establishing Regulatory Frameworks and Industry Standards

The Chinese government has introduced strict regulations for battery collection, transportation, and recycling. These measures ensure traceability and safety throughout the battery lifecycle, setting a benchmark for other countries.

More than 80% of China’s spent EV batteries are now processed through certified channels, ensuring compliance and public safety.

India’s draft Battery Waste Management Rules 2022 are a step in this direction, aiming to build a transparent and efficient recycling ecosystem.

China’s leadership in EV battery recycling demonstrates that sustainable growth and technological innovation can go hand in hand. As India accelerates its own EV adoption, adapting and localising these best practices will be crucial to achieving both environmental and economic resilience in the years ahead.

Sources

Original Source

google.com - Read original

Official Sources

- Intergovernmental Panel on Climate Change (IPCC): IPCC opens registration of experts to review the first draft of the Methodology Report on Inventories for Short-lived Climate Forcers

Quotes

- Publishing Domain: google.com

- Published Date: 2025-12-15T10:11:25+05:30

- Original URL: Read original (news.google.com/rss/articles/CBMitgFBVV95cUxPVktlOGFtbExqTFVXR1lPSzdCalhwc… …)

Editorial Check

- Originality: 40 / 100 — The summary provided is essentially a repetition of the article title and source, offering no unique phrasing or additional insight. This is a common format for news aggregation and does not demonstrate original content.

- Helpfulness: 10 / 100 — The summary gives minimal information beyond the article’s title and source, lacking any substantive details about how EV battery recycling contributes to China’s sustainability. It does not help the reader understand the content or significance of the article.