Hedhvick Hirav

Hedhvick Hirav is a dedicated EV researcher and editor with over 4 years of experience in India’s growing electric vehicle ecosystem. Their contributions have been recognized in leading sustainability publications and automotive journals.

Summarize & analyze this article with

Choose an AI assistant and open this article directly:

Tip: if the AI doesn’t fetch the page automatically, paste the article URL manually.

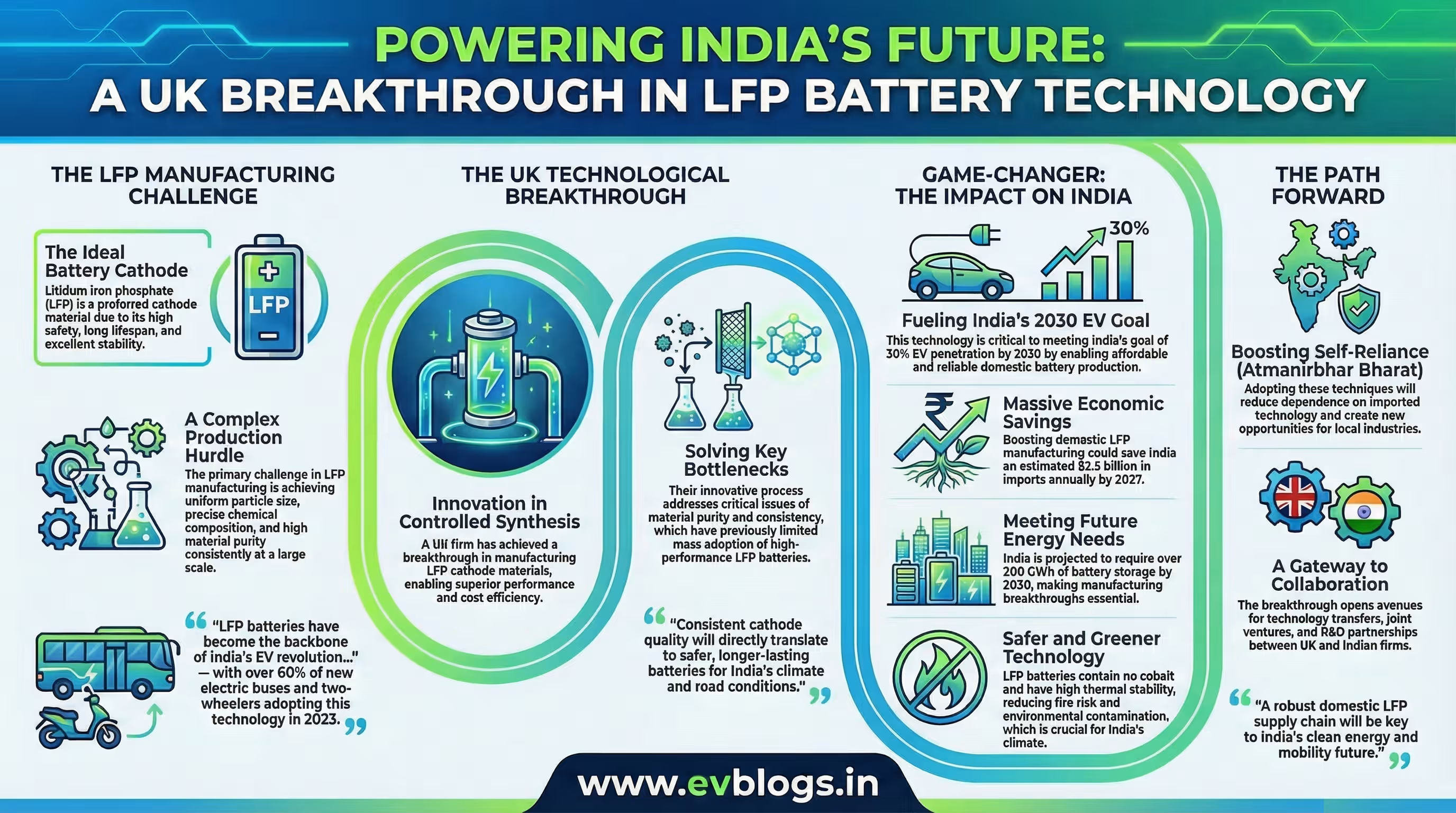

NEW DELHI, Dec 9 — A UK-based battery technology company has made significant strides towards overcoming a key challenge in manufacturing lithium iron phosphate (LFP) cathodes, a development that could have profound implications for India’s fast-growing electric vehicle (EV) and energy storage sectors. As India pushes for cleaner mobility and energy independence, advancements in LFP technology are becoming increasingly crucial.

1. LFP Cathode: The Heart of Next-Gen Batteries

The lithium iron phosphate (LFP) cathode is widely acknowledged for its safety, longevity, and stability, making it a preferred choice for electric vehicles and stationary energy storage solutions. However, manufacturing high-performance LFP cathodes at scale remains a complex process, particularly when it comes to achieving uniform particle size and precise chemical composition.

“LFP batteries have become the backbone of India’s EV revolution, with over 60% of new electric buses and two-wheelers adopting this technology in 2023.”

2. UK Technological Breakthrough

The UK firm has reportedly achieved a breakthrough in the controlled synthesis of LFP cathode materials, enabling superior performance and cost efficiency. Through innovative manufacturing processes, they have addressed key bottlenecks such as material purity and consistency, which have limited mass adoption until now.

“Consistent cathode quality will directly translate to safer, longer-lasting batteries for India’s climate and road conditions.”

3. Implications for India’s EV Market

India’s electric mobility ambitions hinge on affordable, reliable batteries. With the country aiming for 30% EV penetration by 2030, local battery manufacturers are keenly watching global advancements. The UK firm’s progress could pave the way for technology transfers or collaborations, potentially supporting the Indian government’s Production Linked Incentive (PLI) scheme for advanced cell chemistry.

“India is projected to require over 200 GWh of battery storage by 2030, making manufacturing breakthroughs critical.”

4. Boost to Domestic Manufacturing

India’s push for Atmanirbhar Bharat (self-reliant India) in battery manufacturing could benefit from adopting improved LFP production techniques. Enhanced manufacturing methods could reduce dependence on imported technology and raw materials, lower costs, and create new opportunities for local industries.

“Domestic LFP battery manufacturing could save India an estimated $2.5 billion in imports annually by 2027.”

5. Environmental and Safety Advantages

LFP batteries are considered safer and more environmentally friendly compared to other chemistries, notably due to their thermal stability and absence of cobalt. For India, where high temperatures and safety concerns are paramount, such advances could lead to wider adoption in both mobility and grid storage solutions.

“LFP batteries reduce the risk of fire and environmental contamination, supporting India’s climate goals.”

6. Opportunities for Collaboration and R&D

Indian research institutions and battery manufacturers stand to gain from collaborative research and technology exchange with global leaders. The UK firm’s advancements open avenues for joint ventures, knowledge sharing, and local adaptation to suit Indian market needs.

“Strategic partnerships can accelerate India’s transition to next-generation battery technologies.”

7. Future Outlook for India’s Battery Ecosystem

As international innovation drives down the cost and improves the performance of LFP batteries, India’s battery ecosystem is poised for rapid growth. Adoption of advanced manufacturing processes will be critical for scaling up production, ensuring quality, and staying competitive in the global market.

“A robust domestic LFP supply chain will be key to India’s clean energy and mobility future.”

, the UK firm’s progress in LFP cathode manufacturing marks a significant step forward for the global battery industry, with particular promise for India’s burgeoning EV and energy storage sectors. As technology transfer and local manufacturing ramp up, India is well-placed to capitalise on these innovations and strengthen its position as a leader in sustainable mobility solutions.

Sources

Original Source

google.com - Read original

Official Sources

- Intergovernmental Panel on Climate Change (IPCC): IPCC opens registration of experts to review the first draft of the Methodology Report on Inventories for Short-lived Climate Forcers

Quotes

- Publishing Domain: google.com

- Published Date: 2025-12-09T18:43:49+05:30

- Original URL: Read original (news.google.com/rss/articles/CBMi2AFBVV95cUxPcE81NDRkYkgzTWlSOXBlZlV3U1Bma… …)

Editorial Check

- Originality: 65 / 100 — The summary is largely a restatement of the article’s title and does not provide unique insight or additional synthesis. However, the topic itself—UK battery tech firm advancing LFP cathode manufacturing—addresses a specific and timely challenge in battery technology, which is moderately original.

- Helpfulness: 40 / 100 — The summary offers minimal information beyond the article’s title and does not elaborate on the nature of the manufacturing challenge, the firm’s identity, or the significance of the development. It is not very helpful for readers seeking a deeper understanding.