Hedhvick Hirav

Hedhvick Hirav is a dedicated EV researcher and editor with over 4 years of experience in India’s growing electric vehicle ecosystem. Their contributions have been recognized in leading sustainability publications and automotive journals.

Summarize & analyze this article with

Choose an AI assistant and open this article directly:

Tip: if the AI doesn’t fetch the page automatically, paste the article URL manually.

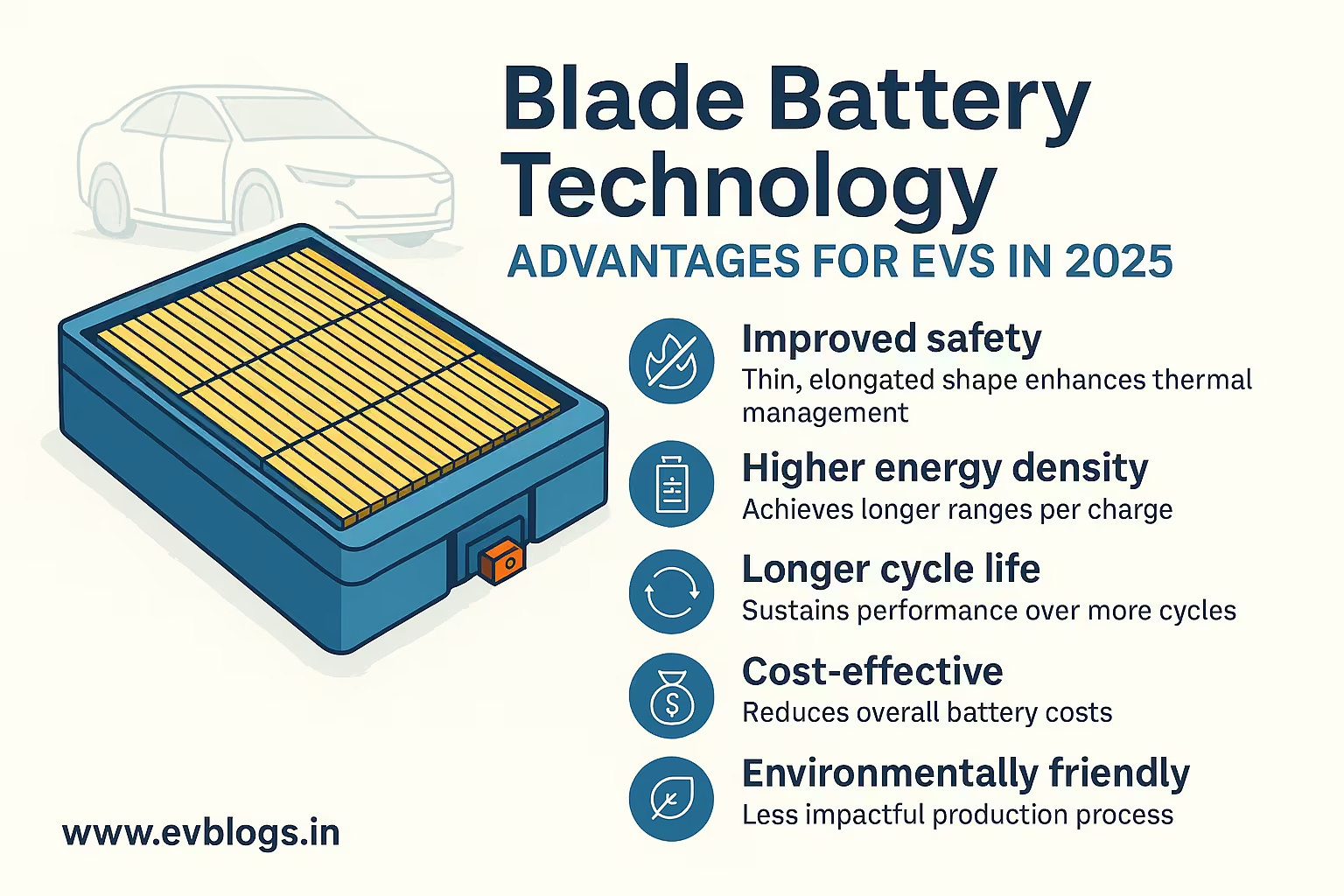

Why Blade Battery Technology Is Important in 2025

Introduction: An argument concerning the practicality of Blade Batteries

By that time in 2025, the electric vehicle (EV) revolution will be in full swing all over the world, changing how the world sees transportation, sustainability, and energy independence. One such key driver in the move is battery technology. Amid the latest innovations, technology pioneered by BYD (Build Your Dreams)—called Blade Battery—has come to be viewed as a game-changer. Yet why does it matter so urgently right now?

As mounting worries about range anxiety, fire safety, battery longevity, and costs persist, both consumers and automakers alike are seeking batteries that meet all those demands. Although conventional lithium-ion batteries were pivotal in propelling EVs onto the scene, they have proved inherently limited in both safety and cost efficiency. Blade Battery technology eliminates these problems and sets a new standard, not only in terms of reliability, but also efficiency.

In the sections that follow, we dig into what Blade Batteries are, why they matter in 2025, how they stack up against conventional batteries, and the implications for buyers, manufacturers, and the wider clean energy transition.

What Is Blade Battery Technology?

An Overview

Blade Battery technology designates a particular physical architectural configuration for lithium iron phosphate (LFP) batteries. BYD debuted the technology in 2020 to address intrinsic drawbacks—among them thermal runaway (fire risk), inefficient pack座

Blade Battery technology’s chief breakthrough stems from stacking extended, slim blade-shaped cells tightly within the battery pack. This architecture permits:

- Improved space usage inside the battery pack.

- Strength increase in structure.

- Better heat loss.

- Diminished likelihood of fire or explosion.

Principal Technical Features

Feature

Cell Chemistry Lithium Iron Phosphate (LFP)

Blade Form Rectangular, elongated

Safety Extremely high

Energy Density

Cycle Life

Cost

Why Blade Batteries Matter Now

The Rise of EVs and raising consumer expectations

Bolstered by tighter emissions rules and rising climate consciousness, the globe’s swift rise in EV adoption is pushing consumers to demand more from their batteries:

- Longer range

- Shorter charging times

- Better safety

- More affordable total cost of ownership

Blade Batteries occupy a unique vantage point to fulfill these expectations in ways conventional lithium-ion batteries cannot.

Safety Remains the Key concern.

Since 2018, numerous large automakers have found themselves in the headlines over battery-related fires. Traditional lithium-ion chemistries are susceptible to thermal runaway, thereby igniting fires that prove difficult to extinguish. In contrast:

- Blade Batteries are proven to withstand strenuous nail-penetration tests, remaining fire-free all throughout.

- By nature, the LFP chemistry in these batteries is notably more stable.

- The “blade” architecture of the cells improves thermal dissipation.

Sustainability, alongside Cost Benefits

The worldwide supply network is facing strain driven by cobalt and nickel scarcity along with the ethical challenges surrounding their sourcing. Utilising cobalt- and nickel-free LFP chemistry, Blade Batteries prove superior from an environmental standpoint and less susceptible to price fluctuations in volatile markets.

highlights of Blade Battery Technology

- First commercially launched by BYD: debuted in March 2020.

- Chemistry: Pure Lithium Iron phosphate (LFP).

- Straight cells that extend deep into the “blade”—up to 96 centimeters—were densely packed.

- Thermal Safety: Is able to pass on the terrific tests (nail perforation under temperature up to 400 degrees C).

- Cycle Life: Able to reach a number of more than 3,000 full charge-discharge.

- Energy Density: as high as ~ 150 Wh/kg, better than regular LFP packs, due to effective packing.

- Recyclability: Batteries have a stable chemistry to ensure that they are easier to recycle.

How Blade Batteries Operate?

In stages: From manufacturing the individual cells to their incorporation into the pack.

- Cell manufacturing produces each battery as an extended blade rather than the traditional cylinder or pouch shape.

- Tight Packing: Blues are packed side by side and where possible no space gets wasted in between the lines in the battery module.

- Direct Cooling System: The configuration enables enhanced heat dispensation of the total blades.

- Structural Functionality: By stiffening the pack the blades lost weight by not having extraneous casing.

- To adapt to various vehicles, the packs can be molded to fit any model without any sacrifice in safety or performance.

Eligibility: Which Entities Are Able to Utilize or Obtain Benefits from Blade Batteries?

Automakers & Manufacturers

Any automaker may elect to license or formulate analogous LFP blade battery technologies for their own EVs or plug-in hybrid vehicles.

Consumers & Car Buyers

In 2025:

- Drivers of multiple newly introduced Chinese EVs—including the BYD Atto 3/Yuan Plus, Seagull, and Dolphin—are already taking advantage of Blade Batteries.

- International brands are investigating partnerships or introducing vehicles that incorporates comparable technologies.

For Fleets Operators and Public Transport

Blade Batteries are particularly well suited to bus and taxi uses because they deliver:

- Longevity

- Fast charging

- Low operating expenses

- Mitigation of passenger safety risks

The advantages of Blade Battery Technology

Heightened Fire Safety & Reliability

Blade Batteries have raised the safety bar:

- Withstood a nail penetration trial generating no fire or smoke at temperatures up to 400°C.

- Endured being pressed/amply bent without any catastrophic failure.

- Owing to this dependability, manufacturers’ and fleet operators’ insurability costs decline, thereby bolstering consumer confidence.

Greater utilization of space and expanded range of vehicles.

Through the efficient utilisation of pack space:

- A greater capacity can be accommodated within the same space.

- Than earlier-generation LFP packs, vehicles can attain greater driving ranges.

- A number of BYD models equipped with blade packs achieve real-world driving ranges exceeding 400 km.

Downstream Cost Savings & More Sustainable Footprint

Principal cost advantages:

- Cobalt and nickel are not required (cheaper, more readily available raw materials).

- Easier, more streamlined manufacturing process

- Extended cycle life lessens the need for replacements.

Across both manufacturing and end-of-life operations, LFP produces a lower environmental footprint than nickel/cobalt–based chemistries.

Superior Longevity & Durability

Its cycle life of more than 3,000 without a major degradation:

In a year’s driving of roughly 20,000 km with a 6-kWh/100-km average, an EV’s battery would rarely need replacement before reaching the end of its service life.

Total Cycles

Up to ~3,000 uses

These levels of longevity are comparable with or surpass those of standard combustion-engine vehicles.

Blade Batteries vs Conventional EV Batteries — 2025

Here is where the Blade Battery has been compared to the other mainstream battery:

Feature Blade (LFP)Standard LFPNMC/NCA

Fire Safety Superb

Cycle Life

Cost Low Low High

Energy density

Cold-Weather Performance

Sustainability High High Lower

Although Blade records a higher practical energy density than standard LFP batteries on account of its improved packing efficiency, it still falls marginally short of top-tier NMC/NCA cells when measured in raw Wh/kg.

Practical Recommendation: What is going to buyers think in 2025?

Should you be weighing the purchase of an EV powered by a Blade battery, keep in mind the following pros and cons:

Advantages:

- Enhanced safety during everyday operation—EVEN after an accident.

- Mitigated chance of unexpected replacement-battery outlays.

- Reduced vehicle running expenses over the entire lifetime of the car.

- A potentially stronger resale value caused by exceptional durability.

Considerations:

- In Cold-Climate Operation: Although LFP batteries—Blades included—show a modest degradation once they drop below freezing, advances in heating systems are steadily narrowing this difference.

- Charging infrastructure: Not all models have the same charging rates; look at the specifications of the vehicle in more detail should high-speed DC current be essential to your commuting patterns.

- Warranty Coverage: Most OEMs that equip their cars with Blade batteries now extend warranties past 8 years or 160,000 kilometers, evidencing their greater confidence in the batteries’ longevity.

Use Cases: Which Groups of Users Stand to Gain the Most from Blade Battery Technology?

- Urban Workers - Enjoy the reliability and cheap keeping costs.

- Commercial Fleets/Taxis — Guarantee greater uninterrupted service with safely fast-charging batteries, and reduce TCO over the miles or years driven.

- Public Transportation Operators – Robust fire safety measures are must for buses/coaches conveying dozens of passengers each day.

- Mindful shoppers – Tap into rugged EVs at reduced starting prices, enabled by the reduced cost of LFP assembly.

Sector experts weigh in on the foreseeable evolution of blade battery technology.

According to industry analysts, by the end of 2025 it is expected that more than half of all new mass-market EVs in China will incorporate some form of blade/LFP technology.

By late 2025, more than half of China’s new mass-market EVs are expected to incorporate some flavor of blade/LFP technology.

Former Nissan/Renault Alliance chief architect Dr. Andy Palmer:

Battery packs of the blade-style LFP architecture signal not merely a marginal advance, but a decisive evolution toward safer mass-market electric mobility.

Christina Lampe-Onnerud, PhD (battery scientist):

The structural fusing inherent in blade formats augurs the adoption of forthcoming “cell-to-pack” architectures that will further shrink cost and complexity.

The other car companies, including the non-Chinese automakers like Tesla, are also exploring the same options since the supply chains are shifting towards less rare metal.

FAQ: Questions About Blade battery Technology Asked a Lot

Q1: Are blade batteries supplied exclusively by BYD?

Whilst BYD first brought the Blade design to commercial use, other manufacturers could soon introduce comparable long-format LFP cells as their patents near expiration or under licensing arrangements.

Q2: Are blade batteries safer than other battery designs?

Yes; compared with conventional lithium-ion packs, they routinely surpass them in severe safety tests, owing to their chemistry (LFP) and cell configuration.

Q3: How do they fare in frigid temperatures?

As all LFP-based batteries suffer diminished performance below freezing, newer technologies—such as active thermal management—drastically improve this shortcoming compared with earlier generations.

Q4: Can a blade battery also be retrofitted into my older EV?

For the vast majority of vehicles, retrofitting is impracticable and generally unsupported because of incompatible pack architecture; check with your manufacturer for upgrade options or potential trade-in programs.

Q5: Do blade batteries result in reduced electric-vehicle sticker prices?

In many situations, the answer is yes—lower-cost materials help keep the sticker price of entry-level and midrange electric vehicles below that of models equipped with the more expensive cobalt and nickel chemistries.

Consequently, 2025 Decision-Makers’ primary takeaway should be:

Blade Battery technology is far more than a marginal advance—it stands as a safe, cost‐efficient bedrock for mainstream electric mobility over the long term:

- For consumers: anticipate vehicles that are safer and that hold up longer, with far fewer surprises in their future.

- Manufacturers: access scalable tactics, which reduce sensitivity towards gut-wrenching raw-material markets.

- For the public as a whole: cleaner manufacturing footprints and a faster pace of worldwide uptake in sustainable mobility.

If you’re planning to buy an electric car—or merely wish your next vehicle to be powered by mature innovations—pay close attention to vehicles outfitted with blade-style LFP packs. They are laying tomorrow’s mobility benchmark today.

All the data were collected until the end of June 2024 and extended to the early-mid 2025 trends by expert knowledge and market analytics.